Eventuri Carbon Intake Kit for the Toyota GR Supra A90!

Performance Gain: 17-20hp, 11-20ft-lb

The MK5 Supra Eventuri intake has been developed to provide the turbo with a less restrictive flow path whilst maintaining low inlet temperatures. Heat and Volume are the main considerations when designing an intake for turbocharged engines. In the Supra, the intake system is located next to the exhaust manifold which rapidly heat soaks the engine bay. High temperatures are detrimental for engine performance as the turbo would have to build boost with heated, less dense air and so the only way to ensure IAT’s are kept to a minimum is for a fully sealed intake. This however, results in a restriction with only one stock air feed to draw air in from. During development we noticed an additional opening into the wheel arch area and took advantage of this by adding a secondary feed to our airbox. Furthermore our sealed airbox also has a heat shield with gold reflective to minimise the radiative heat transfer from the exhaust manifold. In order to maximise volume we made the airbox as large as possible with a recess for potential strut braces. The stock convoluted intake tube is replaced with a smooth carbon tube which is also larger in internal volume with a starting internal diameter of 111mm (4.4″) smoothly tapering down to match the turbo inlet. The tube provides a smooth path from the filter to the turbo inlet. Finally we use a custom made high-flow dry filter which is ISO tested for filtration performance and has a larger filtration area than the stock filter.

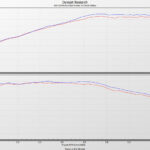

Dyno Testing

Our intake has been independently tested by AMS on a Supra with downpipe and tune. The tests were done back to back on the same day with only the airbox being changed for our intake system. As can be seen there is a performance gain for a large portion of the RPM range with some areas showing over 20hp gain. This is the result of derestricting the inlet path while maintaining low inlet temperatures by keeping a fully sealed system.

Dyno testing an open cone system with the hood open will yield gains but once on the road with the hood closed the heat soak will cause a significant detriment to the power with the open cone sucking in hot air which is a significant problem on the Supra since the intake is directly next to the exhaust manifold and turbo. . With higher air temperature being less dense, the turbo will not make as much boost resulting in lower power. Furthermore, once the car is accelerating and the open cone intake has pulled through the standing hot air present, they will continue to pull in the heat generated by the engine and turbos as they spool. With the engine under load and accelerating, turbos produce a lot of heat which can even be seen with the hot sides glowing red. This is why we designed our system fully sealed.

Another dyno test was carried out in the UK by Evolve Automotive with a downpipe and stage 2 tune. This dyno graph shows the difference between a fully stock Supra and then with the stock airbox, downpipe and stage 2 tune and finally with the Eventuri, downpipe and stage 2 tune. All runs were conducted with the hood closed.

Product Details

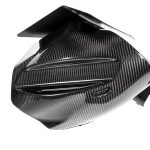

The Eventuri MK5 Supra intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- Carbon Fiber Airbox with Dual Feeds

- Bespoke High Flow Dry Cone Filter

- Carbon Fiber Inlet Tube with 111mm opening ID

- CNC Machined Temperature Sensor Mount

- CNC Machined Breather adapter

- Heat Shield with Gold Reflective Backing

- Laser Cut Stainless Steel Brackets

- Silicon Coupler with OEM Specification Clamps

Crafted from Prepreg Carbon Fiber, the airbox serves 2 objectives – to seal the filter against engine bay heat and to provide a dual cold air feed. Since the airbox is positioned next to the exhaust manifold it is crucial for the filter to be fully sealed so we designed the airbox to encapsulate the filter and at the same time provide a large internal volume. To seal the intake tube we have designed a laser cut plate with a rubber sealing strip which secures to the airbox. The intake tube passes through the plate and the rubber seal ensures heated air does not enter the airbox. To further minimise heat soak, there is an additional heat shield with a gold reflective layer on the exhaust manifold side which effectively combats the radiant heat transfer.

Having a fully sealed airbox results in the problem of having a restriction for the cold air feed. The stock airbox draws air from a single duct which extends to the front bumper area. During development we identified another area to draw cold air from which was a gap between the wheel arch and the chassis on which the airbox sits. To utilise this feed we extended a scoop at the back of our design which protrudes into the wheel arch and can even be seen after installation behind the front wheel. This second feed allows the turbo to draw from a larger area therefore reducing the restriction. Since the scoop extends into the wheel arch area we also incorporated an internal splash guard to deflect water away from the filter. The animation below shows both feeds and also the internal splash guard.

Our final consideration was for race applications where our optional headlamp duct is used for maximum cold air flow. We incorporated a removeable panel on the side of the airbox facing the headlamp so that when the optional duct is used, this panel can be removed for another direct feed of cold air to the filter.

The stock inlet tube has a flexible and convoluted section to provide movement with the engine. This however also adds the possibility of turbulence in the flow path as there are multiple faces which can cause eddies. We replace this with our carbon tube which is smooth and also has a larger internal volume with a huge 111mm (4.4″) opening diameter. The tube smoothly tapers down to the stock turbo inlet to ensure airflow remains as laminar as possible. The tube also has CNC machined fitting for the temperature sensor and the breather adapter.

Our cone filter is made from a non-woven mesh material which is double layered and is ISO tested to ensure that filtration is in line with OEM standards. The filter is cleanable and very stable at high temperatures with the base material being Urethane. The filter incorporates and internal flow guiding cone to help aid the airflow to converge while reducing the possibility of a stagnation point in the middle of the filter space. The filter medium has a significantly larger surface volume than the stock panel filter.

See our website here to order

Civic

Civic  Integra

Integra  NSX

NSX  S2000

S2000  IS

IS  IS-F

IS-F

MX5

MX5  RX7

RX7  RX8

RX8  EVO

EVO  EVO X

EVO X  GTO

GTO  200SX

200SX  300ZX

300ZX  350Z

350Z  370Z

370Z  GTR

GTR  Pulsar

Pulsar  Skyline

Skyline  BRZ

BRZ  Forester

Forester  Impreza

Impreza

Aristo

Aristo  Celica

Celica  Chaser

Chaser  GR Corolla

GR Corolla  GR Yaris

GR Yaris  GR-86

GR-86  GT-86

GT-86  MR2

MR2  Soarer

Soarer  Starlet

Starlet  Supra A90

Supra A90  Supra MK4

Supra MK4